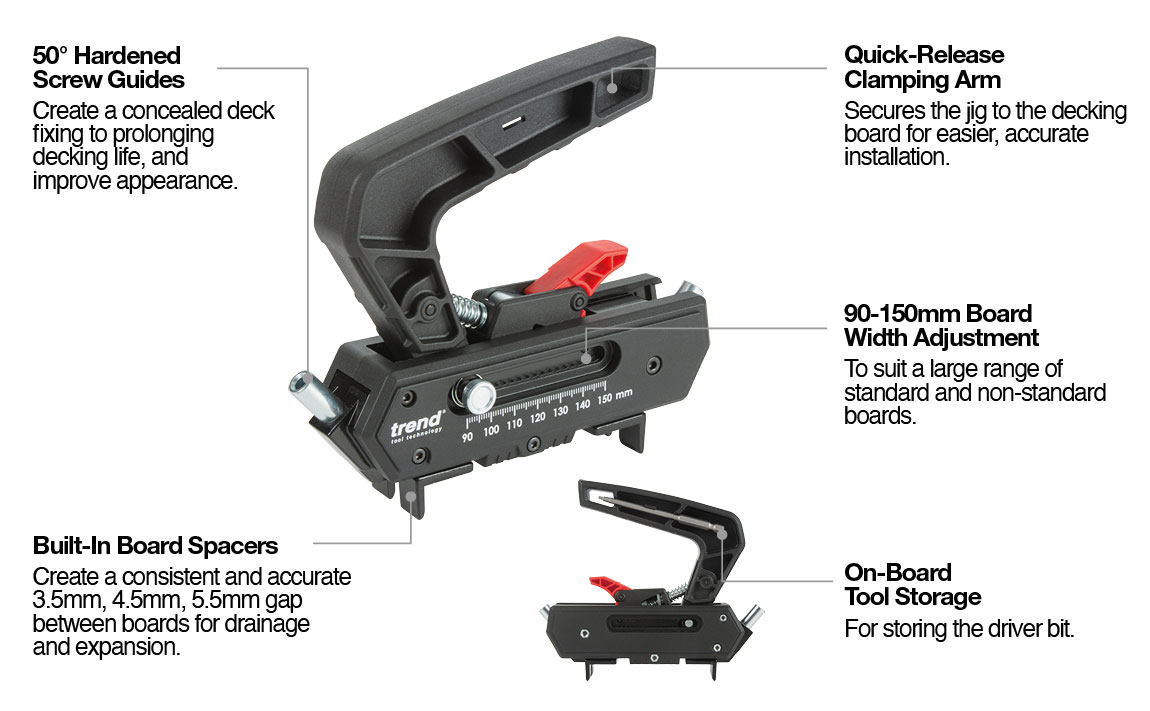

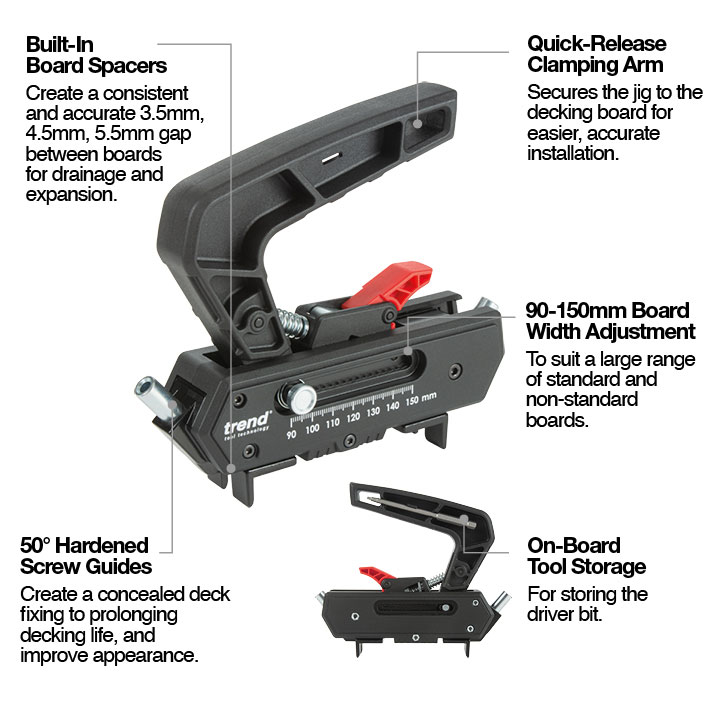

Concealed Screw Deck Jig

Works with Trend’s Ceramic Coated Deck Screws to install decking without visible fasteners. Features built-in spacers to ensure accurate board spacing, built-in clamp with adjustment for varied board widths and hardened screw guides.

Built-In Board Spacers

Hard Angled Screw Guides

Quick Release Clamping Arm

Board Width Adjustment

Features

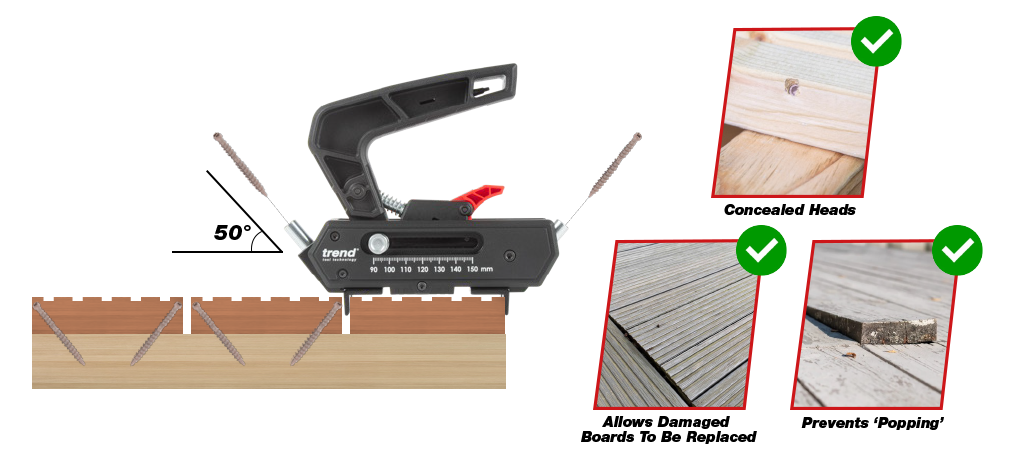

50° Hardened Screw Guides create a concealed deck fixing to prolong decking life and improve appearance.

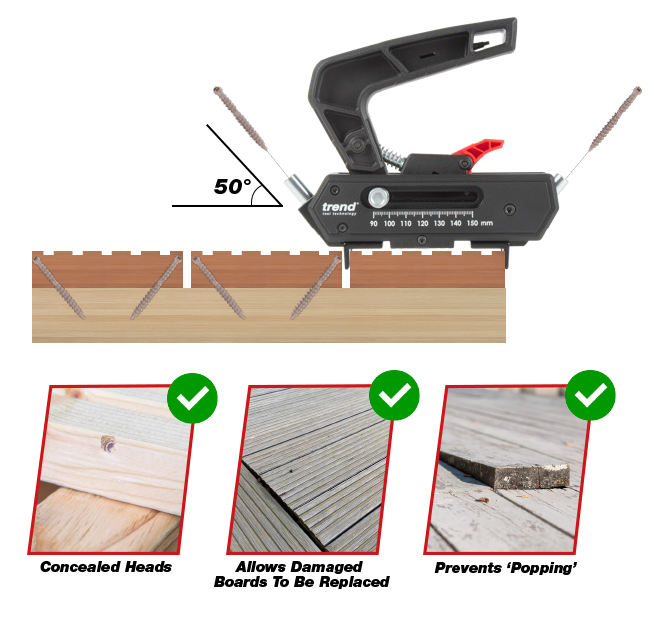

Built-In Board Spacers create a consistent and accurate 3.5mm, 4.5mm or 5.5mm gap between boards for drainage and expansion.

90-150mm Board Width Adjustment to suit a large range of standard and non-standard boards.

Quick-Release Clamping Arm secures the jig to the decking board for easier, accurate installation.

On-Board Tool Storage for storing the driver bit.

Includes hex shank Roberson no.1 bit driver.

50° Hardened Screw Guides

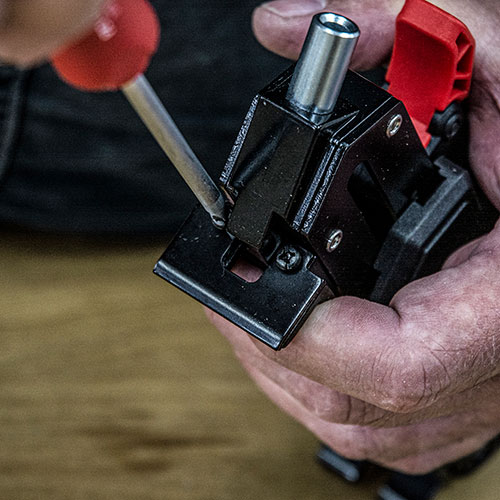

The 50° hardened screw guides refer to specially designed feature incorporated into a the Trend decking jig that facilitates the insertion of screws at an optimal angle. This particular angle ensures that the screws penetrate the deck boards at the right depth, offering enhanced strength and stability to the entire structure. These guides are made from hardened materials to withstand the forces exerted during the installation process and to prevent premature wear and tear.

The Trend Self-drilling, solid steel screws are driven into the sides of the deck boards at an angle, allowing them to be hidden from view once the boards are installed. The result is a clean and polished deck surface without any visible fixings, which significantly improves the overall appearance and creates a professional finish.

The concealed deck fixing method has numerous advantages. First and foremost, it prolongs the life of the decking by minimizing the potential for water penetration and rot. With traditional fixing methods, such as nails or surface-mounted screws, water can seep into the holes or gaps created during installation.

Over time, this moisture can cause the wood to deteriorate, leading to warping, splitting, and overall degradation of the deck. Concealed fixings help mitigate this issue by sealing the deck boards more effectively, reducing the risk of water ingress and extending the lifespan of the decking. The use of 50° hardened screw guides enhances the structural integrity of the deck. The angled insertion of screws creates a stronger connection between the deck boards and the underlying support joists, reducing the likelihood of boards becoming loose or dislodged over time. This increased stability ensures that the deck can withstand heavy loads, foot traffic, and environmental stresses, offering a safe and secure outdoor space for years to come.

Built-In Board Spacers

The primary function of built-in board spacers is to establish a uniform gap between each deck board. These gaps serve multiple purposes, the most important being drainage. By maintaining a consistent spacing between the boards, water can easily flow through the gaps, preventing the accumulation of moisture on the deck surface. This promotes better airflow and allows for efficient drying, reducing the risk of mold, rot, and other moisture-related issues that can compromise the durability of the deck.

In addition to drainage, the gaps created by board spacers accommodate the natural expansion and contraction of the deck boards due to changes in temperature and humidity. Wood and composite decking materials are known to expand and contract as they react to environmental conditions. If the boards are installed without sufficient spacing, they may buckle, warp, or crack when they expand, leading to unsightly deformations and potential hazards. The built-in board spacers provide the necessary room for expansion, preventing such issues and ensuring the overall stability of the deck.

Details

-

50° Hardened Screw Guides create a concealed deck fixing to prolonging decking life and improve appearance.

-

Built-In Board Spacers create a consistent and accurate 3.5mm, 4.5mm or 5.5mm gap between boards for drainage and expansion.

-

90-150mm Board Width Adjustment to suit a large range of standard and non-standard boards.

-

Quick-Release Clamping Arm secures the jig to the decking board for easier, accurate installation.

-

On-Board Tool Storage for storing the driver bit.

-

Includes hex shank Roberson no.1 bit driver.

Featured Products

DK/JIG

Concealed Screw Deck Jig

Works with Trend’s Ceramic Coated Deck Screws to install decking without visible fasteners. Features built-in spacers to ensure accurate board spacing, built-in clamp with adjustment for varied board widths and hardened screw guides.

DK/JIG

U*DK/JIG

(For sale in USA & Canada only)

DK/10X60/750

Ceramic Coated Deck Screws No.10 x 60mm, 750 Pack

Self-drilling, solid steel wood screws designed for use with the Trend® Deck Jig (DK/JIG). Coated with ceramic for superior corrosion protection. 60mm length coarse thread to suit material up to 38mm thick.

- Anti-Corrosion Ceramic Coating provides incredibly durable rust protection. Salt-spray tested to 1000hrs.

- Self-Drilling Tip removes the need for pilot holes and prevents timber splitting.

- Robertson No.1 Square Head provides superior grip to prevent slipping when driving screws at an angle.

- Coarse Thread creates a strong, durable joint in all softwood decking materials.

- EN 14592 Certified for use in timber structures.

DK/JIG/10X60/750

U*DK/JIG//10X60/750

(For sale in USA & Canada only)

Related Products